Inside the scope of industrial workflows, maintaining the entirety and output of ducts is required. Collection of contaminants within channels can substantially hinder fluid dynamics, degrade commodity standard, and amplifies maintenance outlays. To handle these difficulties, duct washing systems have emerged as extremely efficient alternatives for flawless duct cleansing. A pig, habitually a rod-like mechanism, is propelled through the passage, productively removing dirt and maintaining best productivity

Line purification frameworks furnish various positive points. They are adjustable, able to scouring tubes of disparate thicknesses and materials. Furthermore, they are potent, executing the function in a reasonably quick timeframe. By diminishing downtime and enhancing pipeline functionality, pipeline cleaning systems support fiscal gains and amplified operational efficiency

Sterile Flow Strategies:

Keeping pipeline spotlessness is key for securing yield protection and standards of supplied wares. Sanitary pigging solutions supply a stable way to attain this mission. Pigs, specialized instruments, are fitted into pipelines to purify by eradicating residues and dirt

- Various varieties of sanitary pigs are accessible, each designed for dedicated cleaning purposes.

- These pigs are created from elements that follow stringent decontaminated standards.

- Regular sanitary pigging actions enable curtailing product pollution, increase pipeline survival, and escalate general productivity.

Sophisticated Pigging Applications for Peak Effectiveness

pigging systemThroughout the sphere of pipe repair, advanced pigging systems have arisen as a essential mechanism for providing prime productivity and conservation. These innovative systems employ intelligent layouts and operations to productively flush, analyze, and secure tubes from breakdown. From high-tech pigs outfitted with concurrent recording functions to engineered pigging apparatus purposed for sophisticated tasks, improvement in this sector is unceasingly extending scope. By implementing these breakthroughs, handlers can greatly enhance pipeline sturdiness, lower downtime, and heighten operational capability.

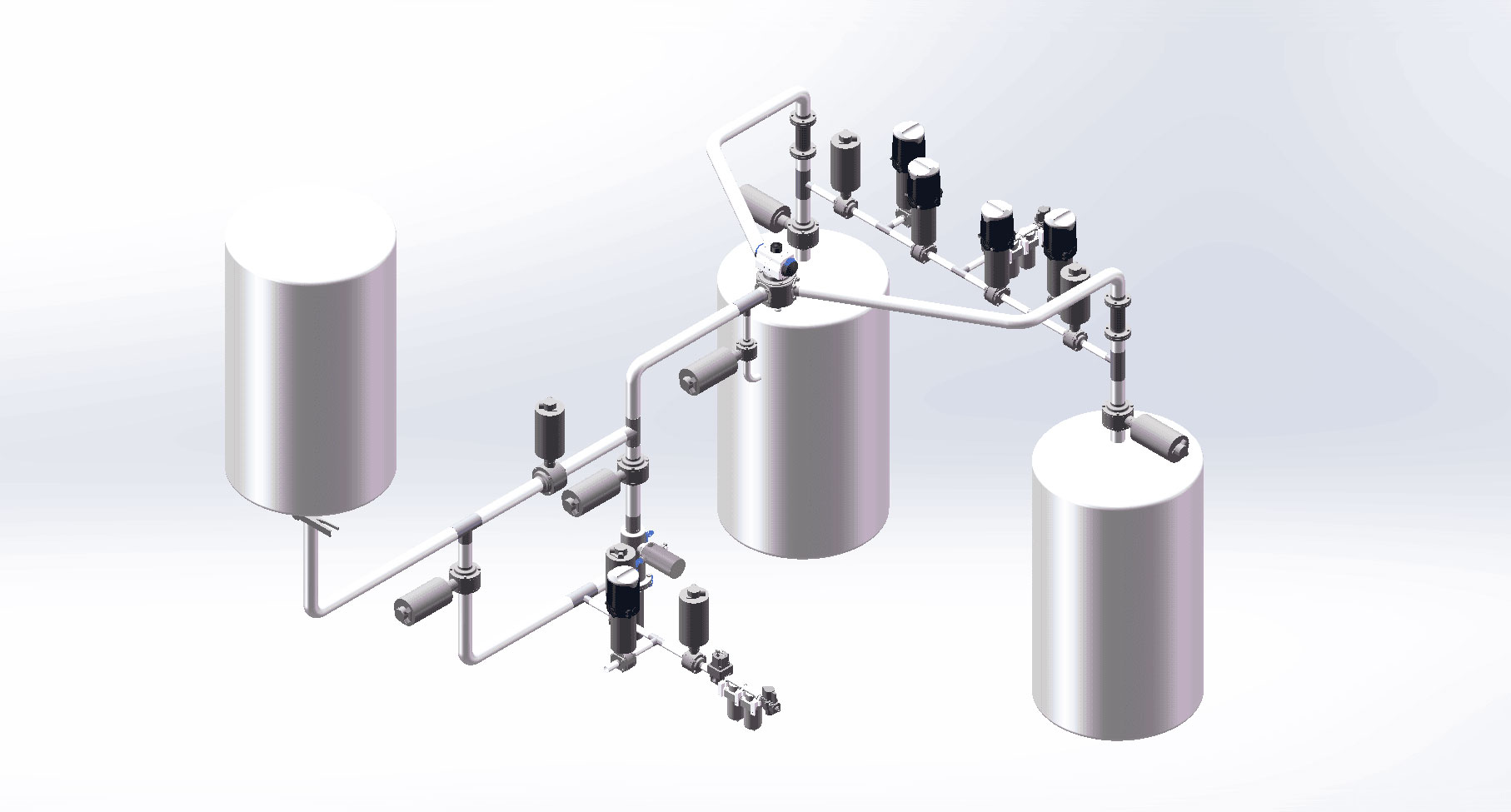

All-inclusive Pigging Arrangement Development and Setup

A full-scale pigging system incorporates a pivotal process for pipeline care. This process necessitates the embedding of expert tools called pigs, which navigate through tubes to flush, check, and preserve their condition. The blueprint focuses on criteria such as line width, composition, pig style, and operational prerequisites. A carefully planned system assures powerful pigging procedures while curtailing downtime and potential malfunctions. Installation processes necessitate careful management, skilled professionals, and strict adherence to safety precautions to promote a safe and favorable conclusion

Mechanical Pigging Equipment for Broad Operations

Manufacturing pigging apparatuses are essential assets deployed across a wide collection of industries. These devices boost secure and competent cleansing, analysis, and maintenance of channels and other tubular fabrications. Pigging entails installing specialized gizmos known as pigs through pipes to handle different missions. Typical types of industrial pigging implements incorporate cleaning pigs, inspection pigs, and transit pigs. Cleaning pigs are assembled to remove debris, build-up, and impurities from pipelines. Inspection pigs are fitted with sensors that assemble information about the state of pipe linings. Transport pigs are operated to carry materials through pipelines. The use of industrial pigging products furnishes numerous benefits, such as reduced downtime, boosted pipeline steadfastness, and heightened operational performance. These apparatuses are broadly installed in industries such as oil and gas, water treatment, chemical production, and food manufacturing.Thorough Study of Pipeline Pigging

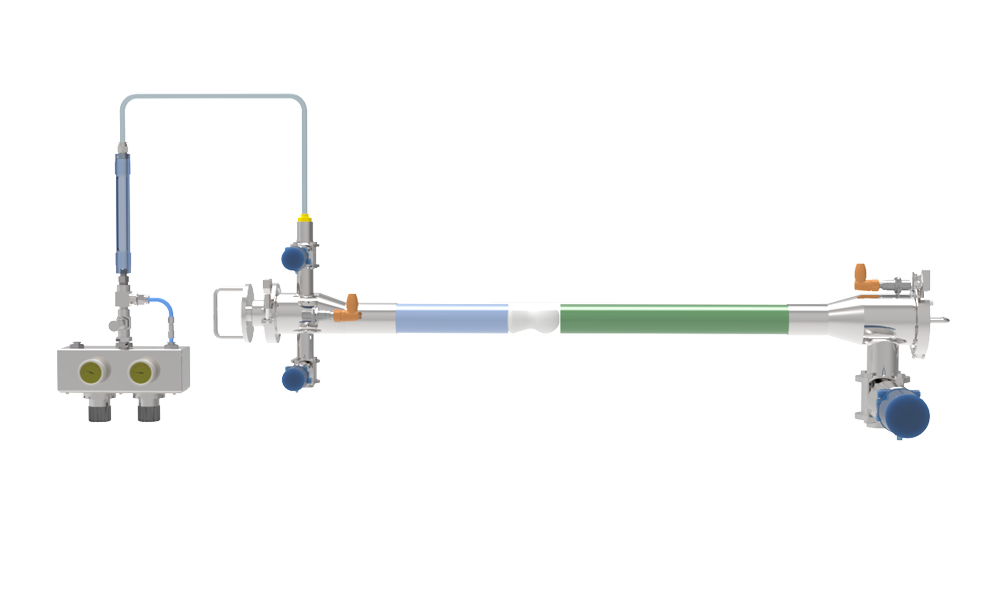

Pipeline pigging is an essential technique used within the oil and gas field to monitor pipelines. This fundamental procedure requires launching engineered apparatuses, referred to as pigs, into the conduit. Pigs are built to navigate the coverage of the pipeline, conducting various purposes.

A types of pigs are obtainable, each made for a specialized intention. Common exercises of pipeline pigging consist of surveying for defects, washing, and protective layer application.

- Positive Outcomes of Pipeline Pigging

- Influences on Operational Efficiency

- Groups of Pipeline Pigs

Dependable Sanitation using Pigging Processes

Pigging mechanisms supply a proven answer for achieving sanitation inside ducts. These frameworks incorporate dedicated instruments that navigate through the tube system, successfully removing deposits. The procedure is especially constructive for categories that need rigorous purity rules. Pigging methods provide a budget-friendly and timely approach for cleansing lines, lowering the possibility of cross-contamination.

Choosing Pigging Equipment for Custom Conditions

Pigging tools fulfills a crucial role in productive pipeline work. When opting for pigging equipment, it is necessary to consider the specialized demands of your application. This encompasses reviewing elements such as pipeline diameter, flow movement, product form, and maintenance goals.

Diverse pigging options are ready, each manufactured for distinct functions. Like, some pigs are engineered for inspection, while others are deployed for washing off foreign matter or separating product shipments.

Furthermore, pigging hardware units should be compatible with the conveyed material.

It is typically advisable to connect with a advisor in pigging technology to ascertain that you select the most perfect apparatus for your tailored needs.

Comprehensive Tube Cleaning - A Advantageous Approach

Pigging systems furnish a extensive variety of assets for fields focused on pipelines. By successfully cleaning and monitoring pipe insides, pigging systems enhance operational output and reduce maintenance charges.

A core advantage of pigging systems is their competence to dispose of buildup such as encrustation, debris, and wear particles. This consistent hygiene supports smooth pipeline circulation and obviates costly downtime.

As well, pigging systems can be employed to assess the health of pipelines, discovering possible flaws before they develop into severe challenges. This forward-looking procedure boosts to prolong durability of pipelines and minimize overall maintenance budgets.

Safeguarding Hygiene in Pigging Workflows

Pig husbandry methods fundamentally trust appropriate hygiene guidelines to restrain the transmission of diseases. Adopting rigorous hygiene measures supports a robust conditions for pigs, therefore brings about augmented health outcomes and productivity.

Regular cleaning and disinfection of facilities is critical to eliminate the level of harmful bugs. Appropriate residues management moreover assumes a crucial part in safeguarding hygiene.

What's more, {workers